Gas-Leak Detection | Buyer's Guide

How to Choose the Right Gas-Leak Detection System for Your Facility

Introduction

Gas leaks pose serious safety risks in industrial environments, from sudden explosions to toxic exposure. These hazards are often invisible and can escalate quickly if undetected. Choosing the right gas-leak detection system for your facility is crucial to safeguard workers, protect assets, and comply with regulations.

With a variety of detection technologies and products available, selecting the best solution depends on your facility’s unique requirements. This guide will help you understand the types of gas-leak detection systems, when and where to use them, and how to select the right system with reference to ESPM SENSE’s comprehensive product range.

What Is a Gas-Leak Detection System?

A gas-leak detection system continuously monitors air quality for hazardous gases and alerts personnel if dangerous levels are detected.

These systems come primarily in two forms:

Fixed Gas Detection Systems: Permanently installed at key locations for ongoing surveillance. Best For Continuous monitoring in permanent areas like storage rooms, process units, and confined spaces.

Portable Gas Detectors: Temporary or mobile monitoring during inspections, maintenance, confined space entry, and emergencies.

By identifying potentially dangerous gases and changes in oxygen levels, these systems provide early warnings that help prevent accidents and maintain safe operations.

Key Benefits of Gas-Leak Detection for Compliance

Each facility has distinct risks depending on processes, materials, and layout. Using the wrong detection system may leave critical areas unmonitored or cause false alarms, leading to unsafe conditions or operational disruptions.

The right system provides:

- Accurate, real-time monitoring tailored to your facility’s hazards.

- Coverage where and when you need it—fixed for continuous protection, portable for flexibility.

- Compliance with industry safety standards.

- Enhanced safety and peace of mind for your workforce.

When to Use Fixed vs Portable Gas Detectors in Your Workplace

Fixed Gas-Leak Detection System

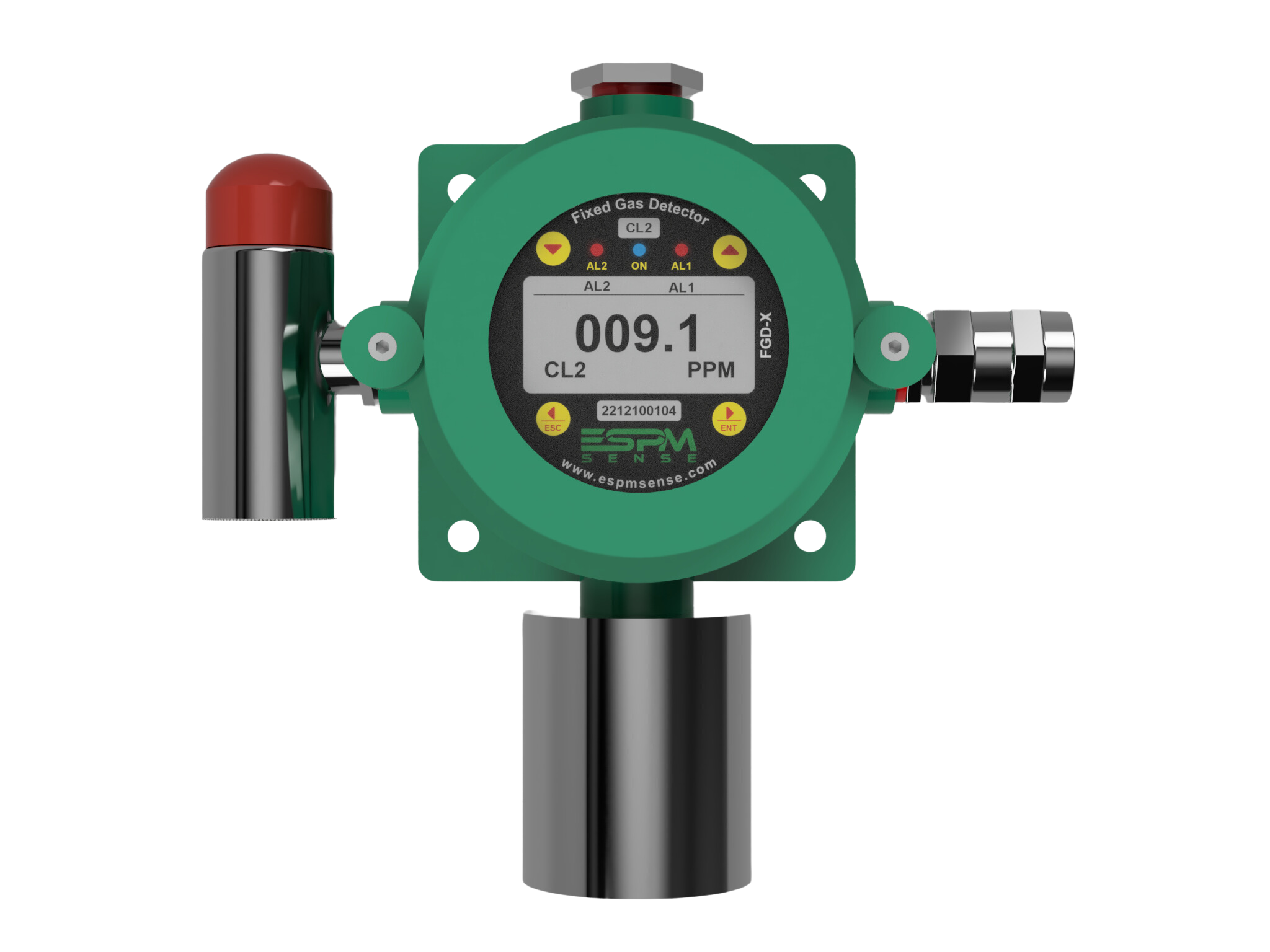

ESPM SENSE’s FGD-X and FGD-X LP detectors offer precise, reliable single-gas detection with flexible deployment options and long-term stability—ideal for permanent facility coverage. The FGD serves as a cost-effective, dedicated single-gas detector where multi-gas coverage is not required.

Storage Areas

process Equipment Zones

Cold Storage and Refrigeration

Portable Gas Detector

ESPM SENSE’s portable gas detectors PGD-X, PDGD-X, and PGD-MAX are designed to meet a variety of monitoring needs in the field. The PGD-X offers reliable single-gas detection for straightforward, cost-effective safety. The PDGD-X expands capabilities by monitoring two gases simultaneously, ideal for tasks with multiple known hazards. For the most comprehensive protection, the PGD MAX provides multi-gas detection, allowing users to monitor several gases at once for complex and dynamic environments.

Confined Space Entry

Maintenance & Repairs

Routine Inspections

remote or Temporary Sites

Emergency Response

How to Choose the Right Gas-Leak Detection System for Your Facility

Identify Hazardous Gases

- What gases are used, stored, generated, or processed?

- Could leaks produce combustible, toxic, or oxygen deficiency risks?

- Are volatile organic compounds (VOCs) part of your operations?

- Under what conditions might off gassing or secondary reactions occur (e.g., heat, pressure, leaks from storage)?

This step defines what kinds of sensors and detection ranges you must support (e.g. sensors for combustible detection, electrochemical sensors, etc.).

Map Out Monitoring Zones

- High risk permanent areas: places like process units, storage rooms, compressor stations, or pipeline headers—areas where a gas leak would have severe consequences.

- Intermediate zones: areas that might occasionally see gas presence or where leaks are rare but possible (e.g. adjacent rooms, pipe corridors).

- Operational & mobile zones: areas where maintenance, inspections, or temporary work happen (e.g. tank tops, ducts, valve pits).

- Confined spaces or inaccessible zones: places where fixed detectors can’t reach, or in which workers must physically enter.

By mapping zones, you know where you need fixed systems vs portable coverage.

Select Detector Type Based on Application

- Fixed detectors in high risk, permanently occupied, or continuously monitored zones.

- Portable detectors for inspections, maintenance, leak surveys, confined space entry, or emergency response.

- For Fixed detectors, ESPM SENSE offers devices like FGD-X and FGD-X LP (loop powered) for point detection in those zones.

- For Portable detectors, you have devices like PGD X (single gas), PDGD X (dual gas), and PGD-MAX (multi gas) for mobile work.

Account for Environmental Conditions

- Temperature range (low/high)

- Humidity, condensation, or moisture exposure

- Corrosive or dusty atmosphere

- Vibration, shock, or mechanical stress

- Placement in hazardous zones (explosive atmospheres, “Zone 1/Zone 2”)

- Cable length, power constraints, and wiring protection

Plan for Calibration and Maintenance

- How often will you calibrate detectors?

- Does the detector support one man, non intrusive calibration (so you don’t need to remove it)?

- What spare parts, sensors, and consumables are needed, and are they available?

- What support does the manufacturer provide (service, calibration, replacements)?

- How easy is it to replace sensors in the field?

- Will the system allow you to track calibration history, alarm events, and diagnostics?

Conclusion

Selecting the right gas-leak detection system is a vital step toward safeguarding your facility and workforce. Whether your needs call for continuous fixed monitoring, flexible portable detection, or a combination of both, ESPM SENSE offers advanced, reliable solutions tailored to diverse industrial environments.

Investing in the right detection system not only ensures regulatory compliance but also enhances workplace safety and operational efficiency.

💡Not sure which gas detection system suits your facility?

Our experts are ready to help you select the best product to meet your safety needs—wherever your facility operates.