The cement industry plays a vital role in infrastructure and construction by producing cement, the key binding material in concrete. It involves processes like raw material preparation, clinker production, and cement grinding. Highly energy-intensive & emission-prone, the industry requires strict safety, dust control, and gas leak detection due to the release of CO₂, CO, SO₂, and dust.

Cement Industry encompasses several processes. Here are some of the key processes in the Cement Industry

Raw Material Handling and Preparation

In the cement industry, raw materials such as limestone, clay, shale, and iron ore are extracted, crushed, transported, and stored. Crushing reduces the size of raw materials, and blending ensures a consistent chemical composition before further processing. This stage involves crushers, conveyors, transfer points, and storage silos.

Types of Gases Present

Dust– Generated during crushing and conveying operations, posing respiratory and explosion risks.

VOCs– Possible if fuel-based additives or solvents are used

Carbon Dioxide (CO2) – Minor emissions from handling carbonate materials like limestone.

Crushers and Conveyor Transfer Points

Dust and particulate matter can leak from crushers and at conveyor transfer points due to material movement and transfer chute gaps.

Fixed Point Detectors: Fixed dust sensors should be installed near crushers, conveyor belts, and transfer points to continuously monitor dust emissions.

Portable Detectors: Portable dust and gas detectors should be used during maintenance and inspection, especially in confined or dusty areas.

Raw Material Storage Silos

Dust and minor gas emissions may escape from storage silo vents and loading/unloading areas.

Fixed Point Detectors: Fixed dust and CO₂ detectors are recommended near silo vents and access points to detect abnormal emissions early.

Portable Detectors: Portable detectors should be used during silo entry, cleaning, or maintenance for worker safety.

Pneumatic Conveying Systems

Leak points can occur at pipe joints or valves in pneumatic systems used for raw material transfer, potentially releasing dust and gases.

Fixed Point Detectors: Fixed dust and gas detectors should be installed at critical joints and along pneumatic conveying lines.

Portable Detectors: Portable detectors should be used when inspecting or repairing pneumatic systems.

Raw Meal Grinding and Blending

In this stage, the crushed raw materials (mainly limestone, clay, and additives) are ground into fine powder known as raw meal. Grinding is done in vertical roller mills or ball mills. The raw meal is then homogenized in blending silos to ensure a consistent chemical composition before entering the preheater. Uniformity in the raw meal is critical for stable clinker formation in the kiln.

Types of Gases Present

Dust– Generated during grinding and material movement; can pose explosion and inhalation hazards.

VOCs– Possible from lubricants, additives, or fuels used in closed-circuit systems.

CO– May be generated in enclosed grinding systems due to poor ventilation or incomplete combustion (if hot gas is used).

Grinding Mill (Ball Mill or Vertical Roller Mill)

Dust leaks may occur around feeding chutes, mill hoppers, and discharge points. CO may also build up in enclosed systems using hot gases.

Fixed Point Detectors: Install dust and CO detectors around the mill housing, near the feed inlet and air outlets.

Portable Detectors: Use portable CO and dust detectors during mill maintenance or inspection, especially when the system is shut down and access is required.

Material Transfer Points and Belt Conveyors

Fine raw meal dust can escape from transfer points, especially where air currents are present.

Fixed Point Detectors: Place fixed dust detectors at key transfer points, especially where raw meal is conveyed between grinding and blending silos.

Portable Detectors: Use portable dust detectors during inspections or maintenance near belt systems.

Blending Silos

Raw meal is stored and aerated in blending silos, which can leak dust through vents and air blowers.

Fixed Point Detectors: Install dust detectors near silo vents and air compressor units.

Portable Detectors: Use portable dust detectors before personnel enter the silo or during repair and cleaning operations

Preheating and Precalcination

In this stage, the homogenized raw meal is fed into a multi-stage preheater tower, where it is heated using hot gases from the kiln. This removes moisture and begins the thermal decomposition of calcium carbonate into calcium oxide and CO₂—a process known as precalcination. Precalciners, located below the preheater, further heat the material using secondary fuel (coal, petcoke, RDF, etc.) before it enters the rotary kiln.

Types of Gases Present

CO2– Released in large quantities due to decomposition of limestone (calcination).

NOx – Formed at high temperatures from nitrogen and oxygen in combustion air.

SO2– May be released if sulfur is present in fuel or raw materials

VOCs– From incomplete combustion of alternative fuels.

CO–Can be produced due to incomplete combustion in preheater or calciner.

Preheater Tower Ducts and Cyclone Stages

High-temperature gases, including CO, CO₂, and SO₂, can leak from flanges, expansion joints, or cracked ducts.

Fixed Point Detectors: Install CO, CO₂, and SO₂ detectors at critical duct joints, especially after cyclone stages and near the base of the preheater.

Portable Detectors: Use multi-gas portable detectors during maintenance, inspections, or when accessing platforms on the preheater tower.

Precalciner (Combustion Chamber)

Incomplete combustion of secondary fuels can lead to CO, NOx, SO₂, and VOC emissions. Leakage can occur from burner lines or chamber seals.

Fixed Point Detectors: Install fixed CO, NOx, and SO₂ detectors around the precalciner and burner system.

Portable Detectors: Use portable multi-gas detectors when checking burner conditions or accessing combustion chamber areas.

Fuel Feed Systems (Solid and Liquid Fuels)

Leakage may occur during handling of coal, petcoke, or RDF, especially near pulverizers and dosing systems. VOCs may also leak from liquid fuels.

Fixed Point Detectors: Install VOC and CO detectors around fuel feeding systems, especially near pulverizer enclosures and fuel pipelines.

Portable Detectors: Use portable VOC and CO detectors during inspection and maintenance, especially when handling or repairing fuel feed lines.

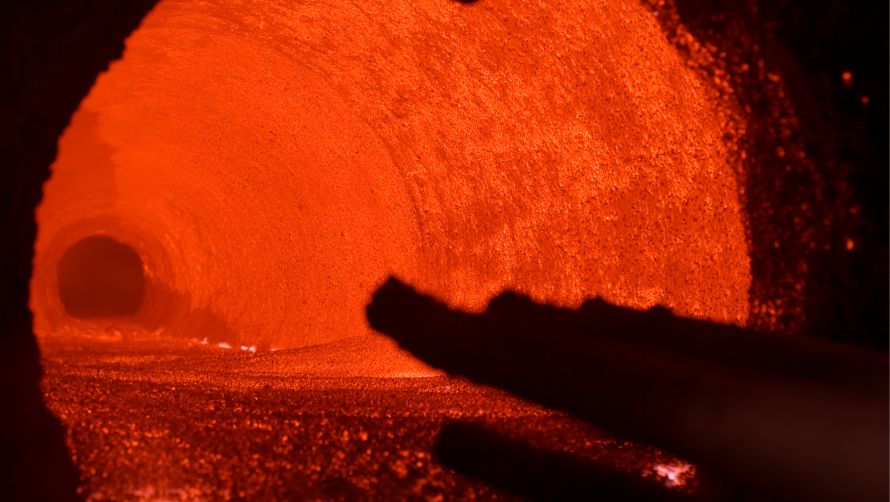

Clinker Production (Rotary Kiln)

In this stage, the preheated and precalcined raw meal is fed into the rotary kiln—a long, inclined cylindrical furnace. Inside the kiln, the material is heated to 1400–1500°C to form clinker, the solid nodules that are the basis of cement. Fuel combustion (coal, petcoke, alternative fuels) provides the necessary heat. This is the most energy-intensive and emission-heavy stage of cement manufacturing.

Types of Gases Present

CO2– Major emission due to both fuel combustion and calcination reactions.

NOx – Generated at high temperatures during fuel burning

SO2– – Emitted from sulfur in fuels or raw materials.

VOCs– Released if alternative fuels (plastics, solvents, etc.) are used.

CO–Released from incomplete combustion inside the kiln.

Dust– Emitted from material handling at kiln feed/discharge ends.

Kiln Inlet and Outlet Seals

These are transition zones where material and gas enter/exit the rotary kiln; leaks may occur due to worn-out or damaged seals.

Fixed Point Detectors: Install fixed CO, CO₂, and dust detectors near the kiln inlet and outlet to capture fugitive emissions.

Portable Detectors: Use portable detectors during kiln shutdowns or seal inspections, especially when thermal stress has degraded seal integrity.

Kiln Burner and Fuel Injection Points

Gaseous leaks can occur at burner assemblies or where fuel (solid, liquid, or gas) is injected. Incomplete combustion may release CO and VOCs.

Fixed Point Detectors: Install CO and VOC detectors near the burner platform and along the burner pipe.

Portable Detectors: Use portable multi-gas detectors when inspecting or maintaining burner nozzles and fuel lines.

Kiln Hood Area

Hot gases and particulates can escape from the kiln hood, particularly when under negative pressure or during maintenance

Fixed Point Detectors: Install CO, SO₂, and dust detectors around the kiln hood and cooler interface.

Portable Detectors: Use portable detectors when entering this high-risk zone for inspection or repair activities.

Clinker Cooling

After exiting the rotary kiln, the hot clinker (at ~1400°C) is rapidly cooled in a grate cooler or rotary cooler using forced ambient air. This rapid cooling stabilizes the clinker’s mineral structure and recovers heat for reuse in the process. The cooling system includes fans, ducts, and dust collectors. This step is crucial for energy efficiency and emissions control.

Types of Gases Present

Clinker Cooler Discharge and Grate Zones

Dust, CO, and residual hot gases may leak through expansion joints, access doors, or cracked ducts in the cooler system.

Fixed Point Detectors: Install fixed CO and dust detectors at discharge points and along the cooler body to monitor emissions.

Portable Detectors: Use portable CO and dust detectors during inspection or when accessing the cooler internals for repair.

Cooler Air Fans and Ducts

Cooling fans and air ducts can leak fine dust and gases, especially around flanges, valves, and inspection ports.

Fixed Point Detectors: Place fixed dust detectors at duct bends, junctions, and around air booster fans.

Portable Detectors: Use portable dust detectors during maintenance checks on fans and ducting systems.

Clinker Transport System (after cooling)

Even after cooling, clinker handling systems (bucket elevators, belt conveyors) can release dust during movement.

Fixed Point Detectors: Install dust detectors along transport paths and at transfer points.

Portable Detectors: Use portable dust detectors during transport line inspections and cleanup activities.

Cement Grinding and Blending

In this stage, cooled clinker is mixed with additives like gypsum, fly ash, slag, or limestone and ground into the fine powder known as cement. Grinding is typically done in ball mills or vertical roller mills. The final cement product is stored in silos before dispatch. This stage involves high-speed mechanical systems, dust generation, and use of blending materials that may also introduce gas or vapor emissions.

Types of Gases Present

Grinding Mills (Ball Mill or Vertical Roller Mill)

Dust and minor CO emissions can leak from mill housings, feed chutes, and discharge ends.

Fixed Point Detectors: Install fixed CO and dust detectors near the mill enclosure, especially at feed and exit points.

Portable Detectors: Use portable detectors during routine inspection and maintenance, especially inside the mill or nearby confined spaces.

Additive Feed Systems (e.g., Gypsum, Fly Ash)

Additive hoppers and conveyors can emit dust and trace gases from handling or reaction with moisture.

Fixed Point Detectors: Install dust detectors at dosing points and additive storage areas.

Portable Detectors: Use portable detectors during manual handling, bag opening, or system cleanouts.

Cement Storage Silos and Transfer Systems

Dust can escape during pneumatic transfer, silo filling, or emptying operations.

Fixed Point Detectors: Install dust detectors at silo vents, compressor rooms, and discharge chutes.

Portable Detectors: Use portable dust detectors during entry or inspection of silos, especially for confined space work.

Storage, Packaging, and Dispatch

Once the cement is ground and blended, it is stored in large silos before being packaged or dispatched in bulk. The packaging process involves filling cement into bags using automated systems, while bulk loading transfers cement directly into trucks or railcars. This phase involves extensive material handling, dust generation, and the use of pneumatic systems, all of which can pose gas and dust hazards.

Types of Gases Present

Cement Silos (Storage and Discharge)

Dust can escape during cement transfer to silos or discharge from them, especially from vents and valve leaks.

Fixed Point Detectors: Install dust detectors at silo tops, vents, discharge chutes, and around air compressor stations.

Portable Detectors: Use portable dust detectors during manual checks, especially when inspecting inside silos or during unplanned discharge issues.

Bagging Machines and Packaging Lines

Automated packaging machines can release cement dust at bag fill points, sealer stations, and during bag ejection.

Fixed Point Detectors: Install dust detectors at fill heads, sealing zones, and conveyor exits.

Portable Detectors: Use portable detectors during machine maintenance, cleaning, or when workers are in close proximity to open systems

Bulk Loading Stations (Truck/Railcar Loading)

Dust clouds may form during cement loading if loading arms are misaligned or seals fail. Enclosed loading areas may also accumulate CO.

Fixed Point Detectors: Install dust and CO detectors at truck loading bays, particularly near loading arms and enclosures.

Portable Detectors: Use portable detectors to check atmosphere inside tankers or during loading line inspections.