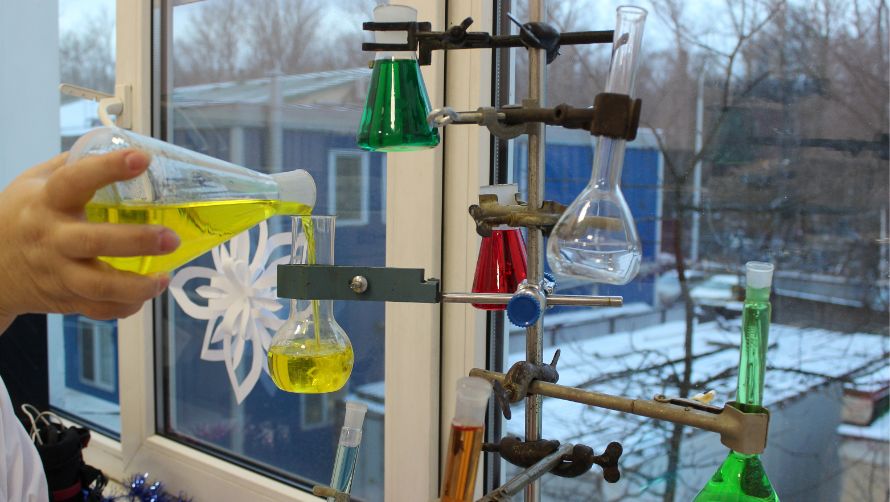

The dyes and dyes intermediate industry plays a vital role in the global textile, leather, paper, plastics, and ink sectors by supplying colorants and the chemical building blocks required for their synthesis. Dyes are complex organic compounds used to impart color to materials, while dye intermediates are raw or semi-processed chemicals that undergo further chemical reactions to form finished Dye Production processes typically involve acids, and solvents, many of which are hazardous and reactive. These processes release various gases such as volatile organic compounds (VOCs), ammonia, nitrogen oxides (NOₓ), hydrogen sulfide (H₂S), and occasionally chlorine or sulfur dioxide.

The dyes and dye intermediates industry encompasses several processes. Here are some of the key processes in the dyes and dye intermediates industry:

RAW MATERIAL PREPARATION

In the dyes intermediate industry, raw material preparation involves handling chemicals that release hazardous gases such as VOCs, ammonia, and sulfur compounds. Ventilation systems expel harmful vapors and ensure safe air quality. Regular inspection of detection and ventilation systems is vital for safety. This ensures a controlled, safe environment throughout the process.

Types of Gases Present

Hydrogen Cyanide(HCN):Extremely toxic, used in dye intermediate synthesis.

Nitrogen Dioxide (NO2): Forms from combustion reactions, toxic

Toluene: Volatile and highly flammable solvent.

Xylene: Highly flammable solvent.

Benzene: Highly flammable and carcinogenic.

Acetone: Common, highly flammable solvent.

Methanol: Flammable solvent.

Ethanol: Flammable.

Cyclohexane: Solvent used in formulations.

Ethyl Acetate: Used as a solvent during raw material handling and mixing.

Oxygen (O2): Essential for some chemical reactions

Storage Tanks

Fixed Point Detectors: Installed in storage tanks and high-risk areas.

Portable Detectors: Used during handling of raw materials

Mixing Vessels

Fixed Point Detectors: Installed in storage tanks and high-risk areas for continues inspection

Portable Detectors: Used during mixing and handling of raw materials

Ventilation Systems

Fixed Point Detectors: Installed in storage and high-risk handling areas to continuously extract hazardous vapors and maintain air quality.

Portable Detectors :Used during raw material handling and maintenance to detect localized leaks of hazardous gases such as ammonia or VOCs in real-time

Dye Synthesis

In the dye synthesis stage, various chemical reactions release hazardous gases such as VOCs, ammonia, hydrogen sulfide (H2S), and nitrogen oxides (NOX).

Ventilation systems, including fume hoods and exhaust fans, are used to remove toxic gases and maintain air quality. Routine checks of gas detection and ventilation systems are essential to ensure a safe and compliant synthesis environment.

Types of Gases Present

Hydrogen Sulfide (H2S): Byproduct of sulfur-based reactions, toxic at low concentrations

Carbon Monoxide (CO) : Byproduct of incomplete combustion.

Nitrogen (N2) : Used in certain processes as an inert gas

Toluene: Volatile and highly flammable solvent.

Xylene: Highly flammable solvent.

Acetone: Common, highly flammable solvent.

Methanol: Flammable solvent.

Ethanol: Flammable.

Cyclohexane: Solvent used in formulations.

Ethyl Acetate: Used as a solvent during raw material handling and mixing.

Oxygen (O2): Essential for some chemical reactions

Reactor Vessels

Fixed Point Detectors: Installed around reactor vessels to continuously monitor for hazardous gases like VOCs, ammonia, and nitrogen oxides (NOx) generated during reactions

Portable Detectors: Used during manual tasks such as raw material charging, sampling, or vessel cleaning to detect localized leaks in real-time and ensure operator safety

Piping Systems

Fixed Point Detectors: Installed at critical points such as joints, valves, and flanges where leaks are most likely to occur. These detectors provide continuous monitoring, especially in enclosed or underground piping routes

Portable Detectors: Portable detectors are employed during inspections, line breaks, or after maintenance activities to check for residual gas leaks along the piping network.

Exhaust Stacks (Chimneys)

Fixed Point Detectors: Installed at the base or within ductwork leading to exhaust stacks to monitor emissions for hazardous gases before release. These systems help in compliance with environmental regulations

Portable Detectors : Portable gas detectors are used periodically during stack inspections, shutdowns, or testing to validate fixed system readings and identify any irregular gas concentrations.

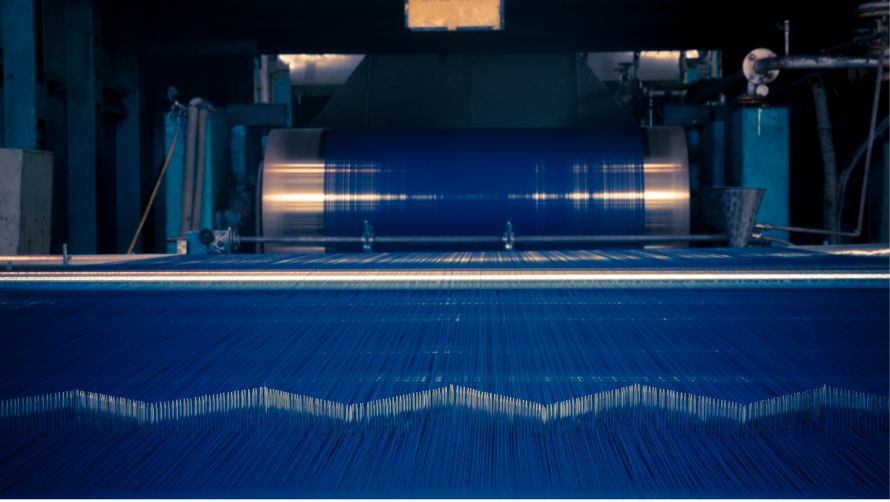

Dye application

In the dye application stage, processes such as dye mixing, dosing, and fabric treatment can release hazardous gases like VOCs, ammonia, and acidic vapors.Ventilation systems, including local exhaust and ducted fans, help remove airborne contaminants and ensure safe working conditions. PPE such as gloves, masks, and goggles is essential to protect workers from chemical exposure.Regular inspection of detectors and ventilation units is critical to maintain safety and regulatory compliance.

Types of Gases Present

Toluene: Used in application, highly flammable.

Xylene: Present in some dye formulations

Chlorine (Cl2) : Used in bleaching & fixation, highly toxic ,corrosive.

Acetone: Flammable solvent used in dye application.

Methanol: Flammable solvent used during dye application.

Ethanol: Used in certain application processes, highly flammable.

Cyclohexane: Solvent used in formulations.

Ethyl Acetate: Present in dye formulation and application.

Oxygen (O2): Present in dye application processes.

Nitrogen (N2) : Used in some dyeing and application methods to prevent oxidation.

Steamers and Pressure Vessels

These chambers are used to apply heat and steam for dye fixation, where leaks of VOCs, methanol, or ethanol can occur.

Fixed Point Detectors: Installed near vent lines and safety relief valves to monitor for leaks or unexpected gas releases during pressurized operations

Portable Detectors: Portable detectors are used during startup, shutdown, or when conducting manual inspections or repairs to confirm safe atmospheric conditions and detect any hidden leaks

Pipes and Connectors

Leaks of VOCs or other solvents during transfer.

Fixed Point Detectors: positioned near joints, flanges, and valves—key areas prone to leaks—especially in pipelines carrying chlorine or other hazardous gases

Portable Detectors: Portable gas detectors are used during routine inspection, pressure testing, or after maintenance shutdowns to verify line integrity and ensure no residual gas remains.

Chlorine Tanks

Chlorine used for bleaching may leak from storage tanks or valves.

Fixed Point Detectors: Installed around storage tanks to provide continuous monitoring for leaks and activate alarms and ventilation if levels exceed safety thresholds

Portable Detectors :Portable gas detectors are used during refilling, inspection, or maintenance tasks to identify localized or small leaks that fixed systems may not immediately detect.

Dye Finishing

In the dye finishing stage, processes such as drying, curing, softening, and chemical finishing can release hazardous gases like VOCs, formaldehyde, and acidic fumes.PPE such as gloves, respirators, and eye protection is essential for workers in finishing areas. Regular inspection of gas detectors and ventilation systems is critical to maintain a safe, compliant, and healthy working environment.

Types of Gases Present

Hydrogen Sulfide (H2S) : May be present during chemical treatments and finishing

Toluene: VOC in the finishing chamber.

Acetone: Flammable solvent

Methanol: Highly flammable solvent used in the finishing process.

Ethanol: Highly flammable, used for washing and finishing

Cyclohexane: VOC in finishing.

Ethyl Acetate: Used in finishing process.

Oxygen (O2): Present during curing, drying, and finishing processes

Curing Ovens

High temperature areas where residual solvents or VOCs can escape.

Fixed Point Detectors: Fixed gas detectors are installed near curing ovens to monitor for VOCs, formaldehyde, and other vapors released during high-temperature curing. These detectors ensure continuous monitoring and trigger ventilation or alarms if limits are exceeded

Portable Detectors: Portable detectors are used during oven maintenance, inspection, or startup to check for gas accumulation and verify safe conditions.

Chemical Treatment Tanks

Fixed Point Detectors: Fixed detectors are positioned around tanks where softeners, resins, or fixatives are applied, to detect hazardous fumes like formaldehyde or acidic vapors

Portable Detectors: Portable gas detectors are used during chemical charging, mixing, or manual operations to identify leaks or unsafe exposure levels in real time.

Exhaust and Ventilation Systems

Fixed Point Detectors: Fixed detectors are integrated within ductwork and near exhaust outlets to monitor gas concentrations before atmospheric discharge.

Portable Detectors : Portable detectors are used for periodic checks during maintenance or troubleshooting to validate exhaust system performance and ensure effective removal of airborne contaminants.