Power plants are complex industrial facilities designed to generate electricity by converting various energy sources such as coal, natural gas, nuclear fuel, or renewable resources into electrical power. These plants operate through a series of integrated processes including fuel handling, combustion, steam generation, cooling, emission control, and power generation. Due to the involvement of hazardous gases, high temperatures, and high pressures, ensuring safety through effective gas leak detection and monitoring is critical to protect personnel, equipment, and the environment.

Our advanced fixed and portable gas detectors provide reliable solutions to help maintain safe operations across all types of power plants.

Here are some of the key processes in the Power Plant.

- Fuel Handling & Storage

- Combustion, Boiler & Steam Generation

- Flue Gas Treatment & Emission Control

- Cooling Systems & Water Treatment

- Gas Handling, Purging & Compression

- Emergency Relief, Flare & Vent Systems

- Generator Cooling (Hydrogen-based)

- Control, Instrument Air & Safety Systems

- Ash Handling & Disposal

Fuel Handling & Storage

Fuel handling and storage is a foundational operation in thermal power plants. It involves the receipt, unloading, movement, and storage of fuels such as coal, oil, natural gas, or biomass. Depending on the fuel type, systems may include conveyors, pipelines, silos, bunkers, tanks, and hoppers. Ensuring safe handling is essential due to the presence of flammable vapors, combustible dust, and potential gas buildup in enclosed or underground areas.

Types of Gases Present

Methane (CH4) – May leak from natural gas pipelines or trapped in coal stockpiles

Hydrogen Sulfide (H2S) – Possible in coal or biomass with high sulfur content

Carbon Monoxide (CO) – Can form in coal/biomass stockpiles due to spontaneous heating

Volatile Organic Compounds (VOCs) – Released from fuel oil or chemical-based fuels

Coal or Biomass Storage Areas (Stockpiles, Silos, Bunkers)

Spontaneous combustion, microbial activity, or decomposition can generate gases like CO or CH₄ inside large piles.

Fixed Point Detectors: Install CO and CH₄ detectors in silos, tunnels, or overhead conveyor galleries; especially near base and mid-levels.

Portable Detectors: Use portable detectors to periodically check gas levels inside confined spaces or during maintenance in stockpile regions.

Fuel Oil or Gas Storage Tanks

Leaks or vapors from tanks and pipelines can release flammable gases like CH4 or VOCs.

Fixed Point Detectors: : Install LEL (Lower Explosive Limit) gas detectors near tank vents, manifolds, and pump stations.

Portable Detectors: Technicians should carry portable LEL and VOC detectors during inspection, loading/unloading, or maintenance.

Conveyor Galleries & Transfer Points

Dust from coal/biomass or minor leaks from gas pipes can accumulate, especially in enclosed or underground galleries.

Fixed Point Detectors: Place CO and CH₄ detectors along covered conveyor belts, junctions, and near mechanical transfer stations.

Portable Detectors: Use portable detectors for hot work permits, pre-entry checks in conveyor tunnels, or during belt maintenance.

Combustion, Boiler & Steam Generation

This process is at the heart of most thermal power plants. Fuel—such as coal, oil, natural gas, or biomass—is burned in boilers to produce high-pressure steam. The steam is then used to drive turbines for electricity generation. Efficient combustion is essential for energy output, but it also involves high temperatures, pressure, and a range of combustible and toxic gases. Boilers, burners, fuel-air mixers, and associated piping are key points where gas leaks may occur, posing risks of fire, explosion, or exposure.

Types of Gases Present

Methane (CH4) – From unburned fuel or gas leaks in burners/pipes

Carbon Monoxide (CO) – Formed during incomplete combustion

Hydrogen (H2)– May be used as a reducing agent in some systems or form during leaks Nitrogen Oxides

(NOₓ) – Byproducts of high-temperature combustion

Sulfur Dioxide (SO2)– Released when burning sulfur-rich fuels like coal or oil

Burner Assemblies

Fuel-air mixtures are ignited here; any imbalance or leakage can result in incomplete combustion or explosive atmospheres.

Fixed Point Detectors: Install LEL/CH4 and CO detectors near each burner assembly and burner front.

Portable Detectors: Use portable LEL and CO detectors during burner startup, shutdown, and inspection activities.

Boiler Furnace & Walls

Furnace leaks or tube failures can release flue gases into adjacent areas, especially during cracks or overheating.

Fixed Point Detectors: : Place CO detectors in boiler enclosures and access points to detect early-stage leakage.

Portable Detectors: Use CO and SO₂ portable detectors when inspecting furnace interiors, especially during shutdowns.

Fuel Gas Supply Lines

Pressurized gas lines feeding burners can leak due to valve faults or joint failures.

Fixed Point Detectors: Install CH4 and LEL detectors along gas lines and near control valves.

Portable Detectors: Use portable CH4 detectors during leak testing, valve servicing, or pipeline maintenance.

Flame Scanners & Igniter Ports

These are entry points into the combustion chamber and can be minor leak zones if gaskets wear out.

Fixed Point Detectors: CO detectors can be installed near observation ports and igniter access doors.

Portable Detectors: Use portable CO/CH₄ detectors when opening these ports during inspection.

Flue Gas Treatment & Emission Control

After combustion, flue gases containing pollutants such as sulfur oxides, nitrogen oxides, particulate matter, and other harmful substances are treated before being released into the atmosphere. This process includes systems like electrostatic precipitators, scrubbers, selective catalytic reduction (SCR), and bag filters. These treatment units reduce emissions and help power plants meet environmental regulations. Because chemicals such as ammonia and sulfur dioxide are involved, gas leaks pose significant health, safety, and environmental risks.

Types of Gases Present

Ammonia (NH3)– Used in SCR systems for NOx reduction; toxic and hazardous

Carbon Monoxide (CO) –Can be present in incomplete combustion residues

(NOX) – Result from high-temperature combustion and NOx control processes

Sulfur Dioxide (SO2)– Produced from sulfur in fuels and present in flue gases

Scrubber Systems

These systems use chemicals to absorb and neutralize SO₂ and other pollutants; leaks can release acidic gases and chemicals.

Fixed Point Detectors: Install SO₂ and NH₃ detectors around scrubber inlets, outlets, and chemical dosing areas.

Portable Detectors: Use portable SO₂ and NH₃ detectors during maintenance or chemical replenishment.

Selective Catalytic Reduction (SCR) Units

Ammonia is injected to reduce NOx emissions; leaks or over-dosing can cause NH₃ slip into the atmosphere.

Fixed Point Detectors: NH₃ detectors should be placed near injection points, catalyst beds, and outlet ducts.

Portable Detectors: Portable ammonia detectors are used during inspection and catalyst replacement.

Electrostatic Precipitators & Baghouses

These filter particulate matter but may have leak points where dust or gases can escape.

Fixed Point Detectors: CO and dust sensors may be installed near hoppers and discharge areas.

Portable Detectors: Use portable CO detectors during maintenance and cleaning cycles.

Cooling Systems & Water Treatment

Cooling systems are essential to remove excess heat from power plants, typically using water or air as the cooling medium. Water treatment units ensure that water used in boilers and cooling circuits meets quality standards to prevent corrosion, scaling, and fouling. Chemicals such as chlorine, ammonia, and acids are often used in water treatment, posing risks of gas leaks or vapor releases. Proper monitoring is critical to protect workers and equipment.

Types of Gases Present

Ammonia (NH3)– Used for pH adjustment and as a corrosion inhibitor

Sulfur Dioxide (SO2)– May be used for dechlorination processes

Chlorine (Cl2) – Used as a biocide in water treatment; highly toxic

Hydrogen Sulfide (H2S) – Can form from anaerobic bacteria in cooling water

Chemical Storage & Dosing Areas

Storage tanks and dosing pumps for chemicals like chlorine and ammonia can leak vapors.

Fixed Point Detectors: Install chlorine and ammonia gas detectors near storage tanks, dosing pumps, and feed lines..

Portable Detectors: Portable detectors should be used during chemical handling, tank filling, and maintenance.

Cooling Towers

Cooling towers can emit vapors containing biocides or other chemicals; leaks can occur in fill media or spray systems.

Fixed Point Detectors: Install detectors for chlorine and ammonia near tower basins and access points.

Portable Detectors: Portable gas detectors are useful during inspection and cleaning.

Water Treatment Plants

Chemical dosing points and reactors may emit toxic gases or vapors during treatment.

Fixed Point Detectors: Place gas detectors in enclosed water treatment areas and near chemical feed points.

Portable Detectors: Portable detectors should be used during routine maintenance and emergency response.

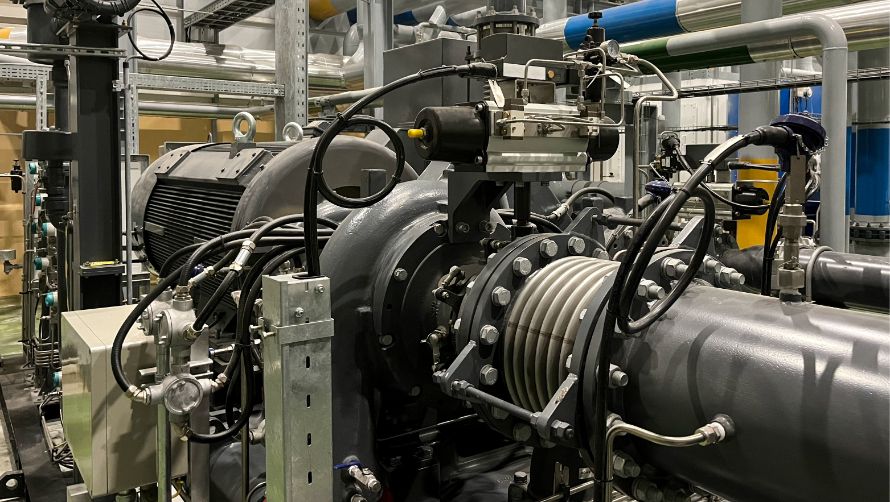

Gas Handling, Purging & Compression

Gas handling in power plants involves the management, purification, compression, and distribution of various gases such as natural gas, hydrogen, nitrogen, and instrument air. Purging systems are used to clear pipelines and equipment of combustible or toxic gases before maintenance or startup. Compressors maintain required pressures for efficient gas flow. Due to the flammable and toxic nature of these gases, continuous monitoring for leaks is critical to ensure plant safety and prevent accidents.

Types of Gases Present

Methane (CH4)– Primary component of natural gas, highly flammable

Hydrogen (H2)– Used in generator cooling and other systems, extremely flammable

Nitrogen (N2) – Inert gas used for purging; asphyxiant in high concentrations

Instrument Air – Compressed air used for instrumentation and control, can contain oil vapors or contaminants

Gas Pipelines & Valves

Pipelines transporting gases can develop leaks at flanges, joints, or valves due to wear or damage.

Fixed Point Detectors: Install LEL (for CH₄, H₂) detectors near critical pipeline sections and valve assemblies.

Portable Detectors: Use portable detectors during maintenance, inspections, and pre-startup checks.

Compressors & Purging Stations

Compressors and purge lines may leak gas due to seal failures or improper operation.

Fixed Point Detectors: Place detectors around compressor seals, vents, and purge lines.

Portable Detectors: Portable gas detectors should be used during compressor maintenance and purging operations.

Gas Storage Tanks & Buffer Vessels

Storage tanks holding gases under pressure can leak through valves, pressure relief devices, or tank walls.

Fixed Point Detectors: Install LEL detectors and oxygen monitors near tank vents and pressure relief valves.

Portable Detectors: Use portable detectors for leak detection during tank filling or servicing.

Emergency Relief, Flare & Vent Systems

Emergency relief systems are critical safety components designed to safely vent excess pressure or hazardous gases from power plant equipment and pipelines. Flare systems burn off combustible gases during emergencies or planned depressurizations, preventing dangerous gas accumulation. Vent systems release non-combustible or low-risk gases safely to the atmosphere. These systems protect equipment integrity and personnel safety but involve handling flammable and toxic gases, requiring effective leak detection.

Types of Gases Present

Methane (CH4)– From natural gas or process vents

Hydrogen (H2)– Used in some cooling or process streams

Volatile Organic Compounds (VOCs)– From fuel oil or process fluids

Carbon Monoxide (CO) – From incomplete combustion in flare systems

Relief Valves & Safety Valves

Valves that release pressure during emergencies can leak gases if seals degrade or valve seats fail.

Fixed Point Detectors: Install LEL detectors near valve assemblies and relief headers.

Portable Detectors: Use portable LEL detectors for valve testing and maintenance.

Flare Headers & Stacks

Flare headers transport combustible gases to flare stacks; leaks can occur at flange joints or piping.

Fixed Point Detectors: Install LEL and CO detectors around flare headers, pilot burners, and stack bases.

Portable Detectors: Portable detectors are used during inspection and flare pilot lighting.

Vent Lines

Vent lines release gases to the atmosphere and may leak at connection points or valves.

Fixed Point Detectors: LEL detectors should be installed near vent line junctions and exhaust points.

Portable Detectors: Portable detectors assist in leak checks and vent system maintenance.

Generator Cooling (Hydrogen-based)

Large power plant generators often use hydrogen gas for cooling because of its excellent thermal conductivity and low density. Some generators may use air or other gases for cooling. Handling hydrogen requires careful leak detection and safety management because it is highly flammable and can form explosive mixtures with air. Proper cooling ensures efficient generator operation and longevity.

Types of Gases Present

Air – Sometimes used, but less common in large power plants

Hydrogen (H2)– Used for cooling generators; highly flammable and explosive

Generator Hydrogen Seal Areas

Seals that keep hydrogen inside the generator can degrade, leading to leaks.

Fixed Point Detectors: Install fixed hydrogen gas detectors around generator seal enclosures and ventilation systems.

Portable Detectors: Portable hydrogen detectors should be used during maintenance or seal replacement.

Hydrogen Supply & Recovery Systems

Hydrogen storage and supply pipelines or tanks may leak due to valve or joint failures.

Fixed Point Detectors: Place detectors near hydrogen supply tanks, compressors, and piping.

Portable Detectors: Use portable detectors during tank filling, supply line inspections, and maintenance.

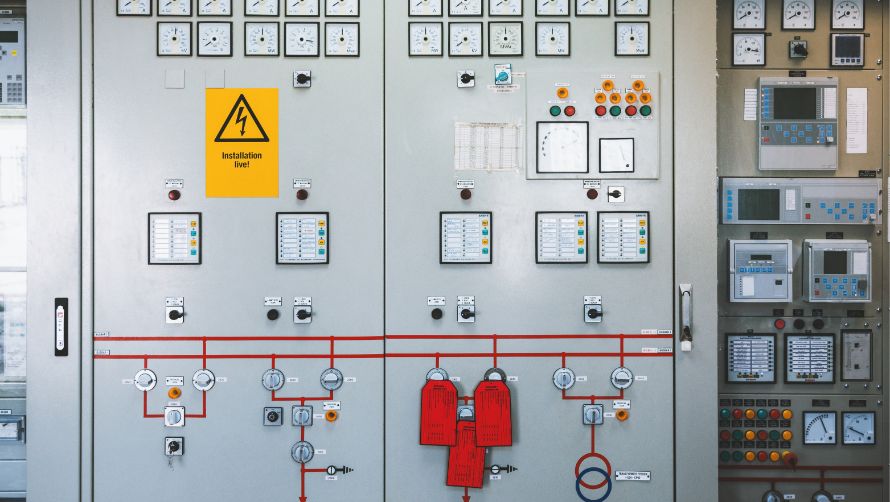

Control, Instrument Air & Safety Systems

Control and instrument air systems supply clean, dry, and oil-free compressed air to operate valves, instruments, and safety systems throughout the power plant. These systems are vital for automated control, emergency shutdowns, and safety interlocks. Contamination or leaks in the instrument air system can lead to equipment malfunction or hazardous situations. Monitoring air quality and detecting leaks ensures reliability and safety.

Types of Gases Present

Instrument Air – Compressed air, sometimes contaminated with oil or moisture (generally non-flammable but critical for safety operations)

Possible contaminants – Oil vapors or other impurities if air dryers or filters fail

Air Compressors & Dryers

Compressors and dryers can leak air or oil vapors due to seal failures or equipment faults.

Fixed Point Detectors: Install detectors near compressor housings, air dryers, and aftercoolers.

Portable Detectors: Use portable detectors for leak detection during maintenance and servicing.

Instrument Air Piping & Valves

Piping networks and valves distributing instrument air can develop leaks at joints or worn components.

Fixed Point Detectors: Fixed leak detectors can be installed at critical valve stations and air distribution points.

Portable Detectors: Portable leak detectors are useful for routine inspections and troubleshooting.

Ash Handling & Disposal

Ash handling involves the collection, transportation, and disposal of ash produced from burning coal or other fuels in thermal power plants. The ash, both fly ash (fine particles collected from flue gas) and bottom ash (heavier residue), must be managed properly to prevent environmental contamination and health hazards. Systems typically include ash hoppers, conveyors, pneumatic transport, and storage silos. Dust and gases emitted during ash handling can pose serious risks.

Types of Gases Present

Dust particles – Fly ash dust containing silica and heavy metals

Carbon Monoxide (CO) – From incomplete combustion residues

Sulfur Dioxide (SO2) – Traces may be present in ash or dust

Methane (CH4) – Possible in anaerobic landfill disposal areas

Ash Hoppers & Conveyors

Dust leaks can occur during ash collection and movement; pneumatic systems may release dust-laden air.

Fixed Point Detectors: Install dust sensors and CO detectors near ash hoppers, conveyor transfer points, and enclosed transport systems.

Portable Detectors: Use portable dust monitors and gas detectors during maintenance and cleaning.

Ash Storage Silos & Disposal Areas

Storage silos can leak dust and gases; landfill or slurry disposal sites may emit methane or other gases.

Fixed Point Detectors: Place dust and methane detectors near silos and disposal areas.

Portable Detectors: Portable gas and dust detectors should be used during inspections and waste handling.