The pulp and paper industry involves complex chemical and mechanical processes that produce paper and related products from raw wood or recycled materials. These operations use and emit various hazardous gases , including toxic , flammable , and corrosive compounds. Key processes such as pulping, bleaching, chemical recovery, lime kiln operation, wastewater treatment, and chemical handling present critical gas leak risks.

Pulp & paper Industry encompasses several processes. Here are some of the key processes in Pulp & paper Industry

Pulping (Chemical Kraft & Sulfite)

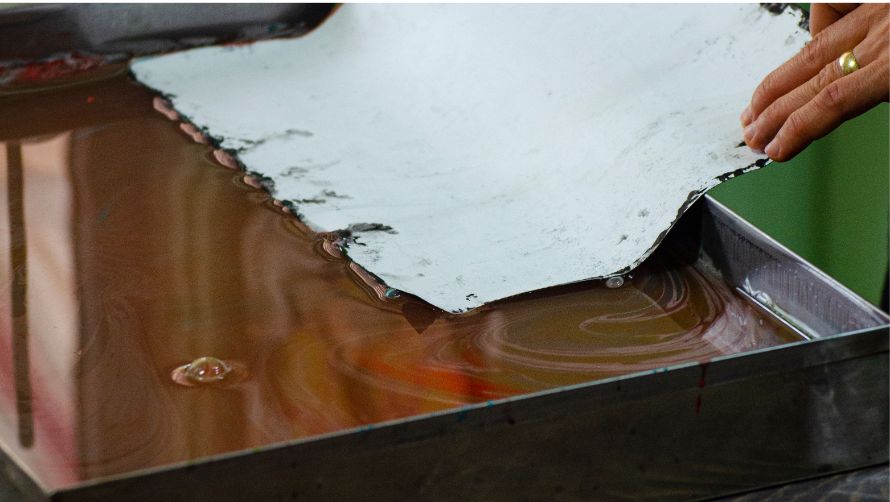

In the pulping process, wood chips are cooked under high temperature and pressure with chemicals (such as sodium hydroxide and sodium sulfide) to break down lignin and separate cellulose fibers. This chemical reaction produces pulp used for paper production, but it also releases odorous and toxic gases that require careful monitoring for safety.

Types of Gases Present

Hydrogen Sulfide (H2S) – A toxic, flammable gas with a characteristic rotten egg smell, produced from sulfur compounds during cooking.

Sulfur Dioxide (SO2)– Corrosive and irritating gas emitted especially in sulfite pulping.

Total Reduced Sulfur Compounds (TRS) – Includes mercaptans and other odorous sulfur gases.

Digesters

Large pressurized vessels where wood chips are cooked with chemicals. Leaks may occur through pressure relief valves, seals, and blowdown systems.

Fixed Point Detectors: Install fixed H₂S and SO₂ detectors near digester tops, relief valves, and blowdown vent areas.

Portable Detectors: Use portable detectors during maintenance, inspections, and when entering confined spaces near digesters.

Blow Tanks & Flash Tanks

Tanks where pressure is released and steam flashes off, releasing odorous and toxic gases.

Fixed Point Detectors: Fixed Detector Installation: Fixed detectors should be installed near vent outlets and around the blow and flash tanks.

Portable Detectors: Portable detectors are essential during cleaning, sampling, and manual handling near these tanks.

Chemical Recovery

Chemical recovery concentrates and burns spent pulping liquor (black liquor) in recovery boilers to regenerate pulping chemicals and produce steam for energy. This process involves handling hazardous and combustible gases released during combustion and chemical reactions.

Types of Gases Present

Hydrogen Sulfide (H2S) – Toxic and flammable gas released from black liquor and smelt dissolving.

Sulfur Dioxide (SO2)– Corrosive gas generated during recovery boiler combustion.

Carbon Monoxide (CO) – Produced from incomplete combustion inside the boiler.

Recovery Boiler

High-temperature boiler where black liquor is burned; leaks can occur from flue gas stacks, furnace doors, and maintenance openings

Fixed Point Detectors: Install fixed CO, SO₂, and H₂S detectors near furnace doors, flue gas stacks, and recovery boiler rooms

.Portable Detectors: Use portable detectors during maintenance and inspection activities around the boiler.

Smelt Dissolving Tank

Tank where smelt is dissolved to produce green liquor; releases H₂S and causes splashing hazards.

Fixed Point Detectors: Place fixed H₂S detectors near vents and around the tank perimeter.

Portable Detectors: Portable detectors should be used when performing maintenance or cleaning inside or near the tank.

Lime Kiln Operation

Lime kiln operation involves calcining lime mud at high temperatures to regenerate quicklime, a key chemical used in the pulping recovery process. This high-temperature process releases combustion gases and requires strict gas monitoring for worker safety.

Types of Gases Present

Sulfur Dioxide (SO2)– Emitted due to sulfur compounds in the lime mud.

Carbon Monoxide (CO) – Produced from incomplete combustion in the kiln.

Kiln Stack and Burner Area

Main emission points where combustion gases exit; leaks can occur through faulty seals or maintenance openings.

Fixed Point Detectors: Fixed CO and SO₂ detectors should be installed near the burner, kiln stack, and maintenance access points.

.Portable Detectors: Portable detectors are essential during start-up, shut-down, and maintenance activities.

Kiln Seals and Access Doors

Description: Potential leaks from worn or damaged seals and kiln access doors releasing combustion gases.

Fixed Point Detectors: Detectors near kiln doors and seal areas to monitor for gas escape.

Portable Detectors: Used during kiln inspection and maintenance to ensure safe air quality.

Bleaching

Bleaching removes residual lignin from pulp using chemical agents like chlorine dioxide, oxygen, and ozone to produce bright white paper. The process involves handling hazardous gases that require vigilant leak detection to prevent exposure and environmental harm.

Types of Gases Present

Chlorine Dioxide (ClO2) – A highly reactive and toxic gas used as a bleaching agent.

Chlorine (Cl2)– Toxic and corrosive gas released during bleaching stages.

Oxygen (O2) – Used in some bleaching methods, can increase fire risk in enriched areas.

Bleaching Tower Vents

Vents and exhausts where residual bleaching gases are released; potential for leaks during pressure changes.

Fixed Point Detectors: Install ClO₂ and Cl₂ detectors near vent outlets and around bleaching towers.

Portable Detectors: Use portable detectors during chemical charging and tower maintenance.

Chemical Storage and Transfer Lines

Pipelines and valves transferring bleaching chemicals pose leak risks due to corrosion or damage.

Fixed Point Detectors: Fixed detectors should monitor chemical storage rooms and transfer pipeline areas.

Portable Detectors: Portable detectors should be used during chemical handling, transfer, and emergency response.

Wastewater Treatment

Wastewater treatment in the pulp and paper industry involves treating effluents to remove organic materials, chemicals, and solids before discharge or reuse. Biological treatment processes such as anaerobic digestion and aeration are commonly used, which can generate hazardous gases requiring proper detection and ventilation.

Types of Gases Present

Methane (CH4)– A highly flammable gas produced during anaerobic digestion of organic matter.

Hydrogen Sulfide (H2S)– A toxic, corrosive gas with a rotten egg odor generated from the breakdown of sulfur compounds.

Carbon Dioxide (CO2) – Produced during aerobic and anaerobic digestion as a natural byproduct.

Anaerobic Digesters

Sealed tanks where organic waste is broken down without oxygen, producing methane and H₂S. Leaks may occur through seals and vent lines.

Fixed Point Detectors: Fixed methane and H₂S detectors should be installed near digester covers, vents, and gas collection points

Portable Detectors: Portable detectors are essential during maintenance, inspection, and confined space entry in digester areas.

Sludge Storage Tanks

Tanks storing untreated or partially treated sludge that can emit methane and hydrogen sulfide gases.

Fixed Point Detectors: Install fixed CH₄ and H₂S detectors around sludge tanks and ventilation ducts.

Portable Detectors: Use portable detectors during sludge handling, transfer, and cleaning operations.

Chemical Storage & Handling

Wastewater treatment in the pulp and paper industry involves treating effluents to remove organic materials, chemicals, and solids before discharge or reuse. Biological treatment processes such as anaerobic digestion and aeration are commonly used, which can generate hazardous gases requiring proper detection and ventilation.

Types of Gases Present

Chlorine (Cl2)– A toxic, corrosive gas used in bleaching and disinfection processes.

Hydrogen Sulfide (H2S) – May be present due to contamination or chemical reactions.

Sulfur Dioxide (SO2) – Released from storage and handling of sulfur-based chemicals.

Chemical Storage Tanks

Large tanks storing liquid chemicals; leaks can occur at valves, seals, and tank vents.

Fixed Point Detectors: Fixed Cl₂ and SO₂ detectors should be installed near tank vents, valve assemblies, and chemical storage rooms.

Portable Detectors: Portable detectors are used during tank filling, maintenance, and emergency response.

Chemical Transfer Pipelines and Valves

Pipelines and valves transferring chemicals between storage and process areas are potential leak points due to corrosion or mechanical failure.

Fixed Point Detectors: Install fixed detectors in chemical transfer corridors and valve stations.

Portable Detectors: Portable detectors are essential during pipeline inspections, maintenance, and chemical transfer operations.