Underground mining plays a critical role in extracting valuable minerals and resources from deep beneath the earth’s surface. These operations are inherently high-risk due to confined spaces, limited ventilation, and the presence of flammable, toxic, and asphyxiating gases. From drilling and blasting to ore transport and dewatering, each stage introduces unique hazards that demand constant gas monitoring to ensure worker safety and operational integrity.

we provide reliable solutions designed to detect gas leaks early, prevent disasters, & protect lives in complex underground environments.

Here are some of the key processes related to Underground Mines

Drilling, Blasting & Ore Extraction

Drilling, blasting, and ore extraction form the initial and critical steps in underground mining operations. Drilling involves creating holes in the rock to place explosives, which are then detonated during blasting to break up the rock mass. Following blasting, the fragmented ore is extracted using various loading and hauling equipment. This process exposes workers and equipment to hazardous gases released from the rock strata and explosives.

Types of Gases Present

Carbon Monoxide (CO) – Toxic gas generated from blasting explosives and incomplete combustion of diesel equipment used during ore extraction.

Methane (CH4)–A highly flammable and explosive gas released naturally from coal seams or organic matter during drilling and blasting.

Nitrogen Oxides (NOx) – Formed as byproducts of explosive detonations and diesel machinery emissions.

Dust and Particulate Matter– Though not a gas, airborne dust is a critical hazard during drilling and blasting.

Blast Holes and Drill Shafts

Methane and other hazardous gases can accumulate in boreholes and shafts after drilling and blasting, creating explosion and asphyxiation risks

Fixed Point Detectors: Fixed methane and CO detectors should be installed near blast holes and drill platforms to provide continuous monitoring.

Portable Detectors: Portable detectors must be used by personnel prior to and during entry into blasted or drilled areas to ensure safe gas levels.

Explosive Storage and Charging Areas

Explosives stored underground may emit toxic gases or vapors that pose health risks in confined storage rooms.

Fixed Point Detectors: Install fixed CO and NOx detectors inside explosive magazines and charging zones to detect leaks early.

Portable Detectors: Portable detectors should be used by workers during handling and charging of explosives for real-time gas detection.

Ore Extraction Zones

Diesel machinery and blasting operations emit CO and NOx gases, especially around loading and haulage areas.

Fixed Point Detectors: Fixed CO and NOx detectors are recommended near extraction faces and haul routes to maintain safe air quality.

Portable Detectors: Workers operating or servicing equipment in these zones should carry portable detectors to monitor exposure continuously.

Ventilation & Airflow Management

Ventilation and airflow management are critical to maintaining a safe underground mining environment by diluting and removing hazardous gases, dust, and heat from mine workings. Fresh air is circulated through the mine via fans and ventilation shafts, ensuring proper airflow to working areas and preventing accumulation of toxic or explosive gases. Proper ventilation also controls temperature and humidity, improving worker comfort and equipment operation.

Types of Gases Present

Carbon Monoxide (CO) – Generated from diesel engines, blasting, and fires; toxic even at low concentrations.

Methane (CH4)–Released from coal seams or organic material, requiring continuous removal to prevent explosive atmospheres.

Radon (Rn) – A radioactive gas that can accumulate in poorly ventilated areas.

Nitrogen Dioxide (NO2) – A toxic gas produced by diesel engines and blasting.

Main Ventilation Shafts

These shafts channel fresh air into the mine but can become points where contaminated air or gases enter if not properly sealed.

Fixed Point Detectors: Install fixed methane and CO detectors at ventilation intake and return shafts to continuously monitor air quality.

Portable Detectors: Portable detectors should be used during shaft inspections and maintenance to ensure safe gas levels.

Auxiliary Ventilation Ducts and Fans

Auxiliary fans and ducts deliver fresh air to specific working areas but may also allow gas leakage if damaged or improperly sealed.

Fixed Point Detectors: Place fixed methane and CO detectors near auxiliary fan outlets and duct junctions to detect leaks promptly.

Portable Detectors: Workers performing ventilation system maintenance should use portable detectors for localized gas monitoring.

Stale Airways and Dead-End Workings

Poorly ventilated or abandoned sections of the mine can accumulate hazardous gases such as methane and CO.

Fixed Point Detectors: Fixed detectors should be installed at critical junctions leading to dead-end tunnels and abandoned workings.

Portable Detectors: Portable detectors are essential when entering these areas for inspections or work to check for dangerous gas concentrations.

Haulage, Transport & Conveying

Haulage, transport, and conveying involve moving ore, waste rock, and materials within the underground mine using vehicles such as trucks, loaders, conveyor belts, and rail systems. These operations are crucial for efficient mine productivity but involve diesel-powered machinery and enclosed spaces, increasing the risk of hazardous gas buildup from exhaust emissions.

Types of Gases Present

Carbon Monoxide (CO) – Emitted from diesel engine exhaust, highly toxic and a major health hazard.

Methane (CH4)–Can accumulate in haulage tunnels, especially in coal mines.

Nitrogen Oxides (NOx) – Formed as byproducts of explosive detonations and diesel machinery emissions.

Diesel Particulate Matter (DPM) – Fine particles from diesel combustion posing health risks.

Diesel Vehicle Exhaust Areas

Exhaust gases from haulage trucks and loaders accumulate in enclosed or poorly ventilated tunnels.

Fixed Point Detectors: Fixed CO and NOx detectors should be placed along haulage routes and loading/unloading points.

Portable Detectors: Operators and maintenance personnel should carry portable gas detectors when working near running engines or in confined transport zones.

Conveyor Belt Galleries

Conveyors may generate dust and allow gas accumulation in confined spaces along their length.

Fixed Point Detectors: Install fixed methane and CO detectors at intervals along conveyor galleries and transfer points.

Portable Detectors: Maintenance workers should use portable detectors during inspections and servicing to detect localized gas pockets.

Loading and Unloading Stations

Areas where ore is transferred between equipment can trap exhaust gases and dust.

Fixed Point Detectors: Fixed detectors for CO and methane should be installed at loading bays and conveyor transfer points.

Portable Detectors: Personnel should monitor gas levels using portable detectors during transfer operations, especially after equipment shutdowns.

Crushing, Screening & Ore Handling

Crushing, screening, and ore handling involve breaking down mined ore into smaller pieces and sorting it by size for further processing. This process generates significant dust and can release trapped gases from the ore. Heavy machinery and conveyors operate continuously, often in enclosed or semi-enclosed spaces, increasing the risk of hazardous gas accumulation.

Types of Gases Present

Carbon Monoxide (CO) – Emitted by diesel-powered crushing and screening equipment.

Methane (CH4)–May be released from certain types of ore, especially coal.

Dust and Particulate Matter – Generated during crushing and screening, posing respiratory hazards.

Crushing Equipment and Feed Points

Dust and gases may be released as ore is fed into crushers, especially in confined areas.

Fixed Point Detectors: Fixed methane and CO detectors should be installed near crusher feed points and housing enclosures.

Portable Detectors: Operators and maintenance crews should use portable detectors when servicing crushers or working in enclosed crushing areas.

Screening Stations

Screening generates dust and can allow trapped gases to escape during material handling.

Fixed Point Detectors: Fixed detectors for methane and CO should be placed near screening decks and dust collection systems.

Portable Detectors: Personnel involved in maintenance or dust control should carry portable detectors to monitor air quality.

Ore Transfer Points and Conveyors

Transfer stations can accumulate dust and gases, particularly in poorly ventilated conveyor galleries.

Fixed Point Detectors: Install fixed methane and CO detectors at conveyor transfer points and galleries.

Portable Detectors: Workers should use portable detectors during inspections or maintenance to detect gas pockets.

Pumping, Dewatering & Drainage

Pumping, dewatering, and drainage are essential processes in underground mining to remove water that accumulates in mine workings. Effective water management prevents flooding and ensures safe, dry working conditions. However, these operations can disturb underground water-bearing strata, potentially releasing dissolved gases and increasing hazardous gas presence in pumped water or nearby air.

Types of Gases Present

Methane (CH4)–Can be dissolved in groundwater and released during pumping.

Hydrogen Sulfide (H2S) – Toxic and corrosive gas sometimes present in mine water or surrounding strata.

Carbon Dioxide (CO2)– May be released from water and strata during dewatering.

Pump Stations and Sumps

Gas can accumulate in water sumps and pump stations where groundwater is collected and removed

Fixed Point Detectors: Install fixed methane, H₂S, and CO₂ detectors near sumps and pump houses to monitor gas release.

Portable Detectors: Operators should carry portable gas detectors when inspecting pump stations or confined sump areas.

Drainage Tunnels and Pipelines

Gas may leak from pressurized drainage pipelines or ventilation shafts associated with drainage tunnels.

Fixed Point Detectors: Fixed methane and H₂S detectors should be installed along drainage tunnels and at pipeline junctions.

Portable Detectors: Maintenance personnel should use portable detectors during inspections of drainage infrastructure.

Water Treatment Areas

Gases released during water treatment or storage can pose inhalation hazards.

Fixed Point Detectors: Fixed gas detectors should be installed in water treatment plants and storage tanks

Portable Detectors: Workers performing treatment operations should use portable detectors to monitor air quality.

Explosives Storage & Charging

Explosives storage and charging involve the safe handling, storage, and loading of explosives into blast holes for detonation. Due to the volatile nature of explosives, strict safety protocols are required to prevent accidental ignition or gas exposure. Gas emissions from explosives and charging processes can create hazardous atmospheres underground.

Types of Gases Present

Nitrogen Oxides (NOx) – Toxic gases produced during explosive reactions and from residual vapors.

Carbon Monoxide (CO) – Generated from incomplete explosive reactions and diesel equipment used nearby.

Ammonia (NH3) – Can be emitted from certain explosive compounds.

Explosives Magazines and Storage Rooms

Confined storage areas can accumulate toxic vapors from explosives over time.

Fixed Point Detectors: Fixed Detector Installation: Fixed NOx, CO, and NH₃ detectors should be installed within storage magazines for continuous monitoring.

Portable Detectors: Personnel handling explosives should use portable detectors to check for vapors during storage inspections.

Charging Stations

Areas where explosives are loaded into blast holes can have localized gas emissions from handling and blasting prep.

Fixed Point Detectors: Fixed CO and NOx detectors should be installed near charging stations to detect hazardous gases during operations.

Portable Detectors: Workers involved in charging operations should carry portable detectors for real-time monitoring of gas levels.

Transport Routes to Blast Sites

Transport of explosives may expose workers to gas vapors released from explosives containers.

Fixed Point Detectors: Fixed detectors are typically not installed along transport routes but monitoring with portable detectors is critical.

Portable Detectors: Personnel transporting explosives should carry portable gas detectors to monitor ambient gas concentrations continuously.

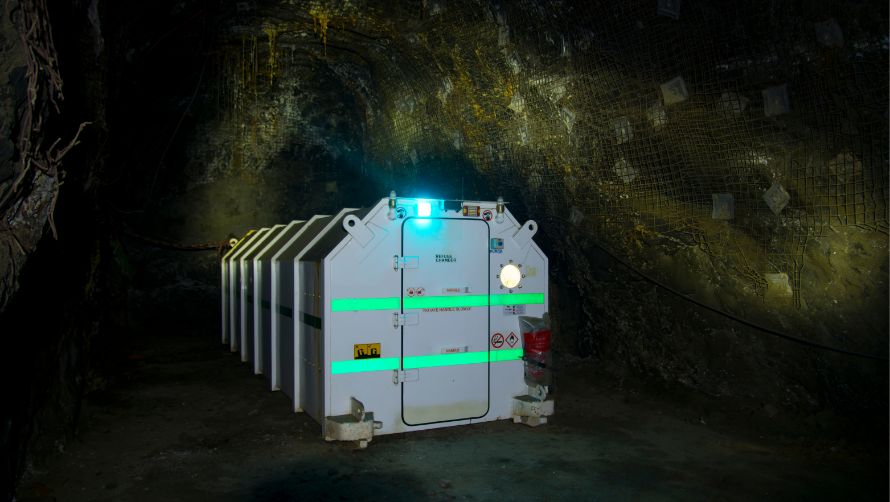

Refuge Chambers & Safety Shelters

Refuge chambers and safety shelters provide emergency safe havens for miners trapped underground due to fires, gas leaks, or collapses. These chambers are designed to supply breathable air and isolate occupants from hazardous atmospheres for extended periods. Monitoring of gas levels inside and around these shelters is crucial to ensure safety and timely rescue operations.

Types of Gases Present

Carbon Monoxide (CO) – Can accumulate due to fires or equipment malfunction nearby.

Methane (CH4) – May accumulate in surrounding mine atmosphere, posing explosion risks.

Carbon Dioxide (CO2) – Exhaled by occupants, increasing concentration inside enclosed shelters.

Oxygen (O2) – Levels can decrease inside shelters, requiring monitoring to ensure breathable air.

Refuge Chamber Interior

Gases such as CO₂ build up inside the chamber from occupants’ breathing, while O₂ levels may drop.

Fixed Point Detectors: Fixed CO, CO₂, and O₂ sensors should be installed inside refuge chambers for continuous monitoring.

Portable Detectors: Rescue teams should use portable detectors to assess air quality inside chambers during rescue operations.

Surrounding Mine Atmosphere Near Shelter Entrances

Hazardous gases like methane and CO can accumulate near chamber entrances in emergency conditions.

Fixed Point Detectors: Fixed methane and CO detectors should be installed around shelter entrances to monitor external air quality.

Portable Detectors: Personnel entering the area should carry portable gas detectors to ensure safe access.

Air Supply Systems

Air supply units connected to refuge chambers must be monitored to ensure no gas contamination occurs.

Fixed Point Detectors: Fixed gas detectors should be installed in ventilation ducts and air supply lines servicing refuge chambers.

Portable Detectors: Maintenance staff should use portable detectors when servicing air supply systems.